Supply Chain Automation

TRG Supply Chain services caters to the supply of automated data collection solutions.

We focus on the implementation of smart but simple to use hardware and software solutions positioned in key operational areas throughout the supply chain.

These are designed to aid not only in automating data collection activities but further aiding in quick guided decision making for operators.

Warehouse Automation

Automating warehousing processes is seen as important, as it provides the ability to deliver higher levels of service as well as reducing costs associated with labour shortages, workplace injuries, and errors. It is also beneficial in terms of maintaining order accuracy, improving customer service, and reducing inventory losses.

In recent years, warehouse automation has been increasingly linked to ERP (enterprise resource planning) software to streamline the entire operation of an organisation. ERP software allows companies to digitally manage all their data, order processing, customer information, inventory control, and financial applications.

The software ensures that the warehouse automation process becomes faster, more accurately managed, and better integrated with other systems. With integration between ERP software and a warehouse automation system, warehouse managers and supervisors can access real-time data which allows them to make more informed decisions when it comes to managing inventory, suppliers, production, and customer orders.

When implementing a warehouse automation system, there are several key features that are required to ensure the system works as it should.

Firstly, the system must be scalable to support the business’s growth, and secondly, the system must be capable of managing and maintaining a high level of accuracy and performance. In addition to this, the system should also be able to integrate with the organisation’s existing ERP software, meaning that the connected systems can both share resources and exchange information.

Overall, warehouse automation is an important consideration when investing in ERP software.

Through integration, the physical processes of warehousing and inventory management can be automated and optimized with the support and controls of enterprise-level ERP software.

riteSCAN Overview

Compatible on Windows PC, Windows Mobile, and Android devices with uniform interface across all platforms. Intuitive interfaces optimized for barcode scanning on touchscreens and mobile devices (including QR Code scanning). Rapidly implemented with live transaction processing with SYSPRO.

Inventory

riteSCAN Inventory extends simple, yet powerful stock management functionality to the warehouse floor by facilitating key SYSPRO Inventory Movement Transactions on to touchscreens and mobile devices. All transactions are validated to SYSPRO ensuring stock holding remains live and accurate at all times.

Manufacturing

riteSCAN Manufacturing delivers on all relevant core transactions as it relates to SYSPRO Work In Progress, the difference however, riteSCAN delivers these for use on handheld scanners, touchscreen PC’s and mobiles devices while delivering on critical warehousing functionality such as pallet management, WIP staging and much much more.

Orders

riteSCAN Orders covers the full spectrum of purchase order and sales order processing. Not only does riteSCAN allow for transaction processing on mobile device, on premise or off, but riteSCAN allows you to do this covering all relevant transaction types, accounting for Lots, Bins and Serials, full label printing integration.

Sales Orders

Flexible configuration options catering to the picking of back order, reserve, or ship line items. Pick standard Sales Orders or SCT’s

Flexible configuration options catering to the picking of back order, reserve, or ship line items. Pick standard Sales Orders or SCT’s

Enhance picking accuracy by utilising mobile devices to ensure items picked are correct to order. Generate dispatch note automatically from the scanner.

Purchases

Receipt stock items directly off the PO creating the SYSPRO GRN and trigger label print. Receive inspection items with a 2 stage receipt.

Receipt stock items directly off the PO creating the SYSPRO GRN and trigger label print. Receive inspection items with a 2 stage receipt.

Incorporate freight apportionment and custom form detail capture. Issue stock received directly to a job on Purchase Order Receipt.

Labour Tracking

Quickly capture time clock and break punches. Track job and task punches as work happens. Track quality and efficiency through capture of completed or scrapped quantities.

Quickly capture time clock and break punches. Track job and task punches as work happens. Track quality and efficiency through capture of completed or scrapped quantities.

Easily integrate SYSPRO WIP transactions such as material issues and job receipts into employee time capture workflow.

Pallets

Group mixed items on one pallet— transfer them to another warehouse or to your shop floor in a single scan. Accurately track, finding mixed materials pallets issued to a job.

Group mixed items on one pallet— transfer them to another warehouse or to your shop floor in a single scan. Accurately track, finding mixed materials pallets issued to a job.

Efficiently stage pallets for sales orders and jobs. Receipt Jobs and Purchases directly to pallets with full integration in riteSCAN.

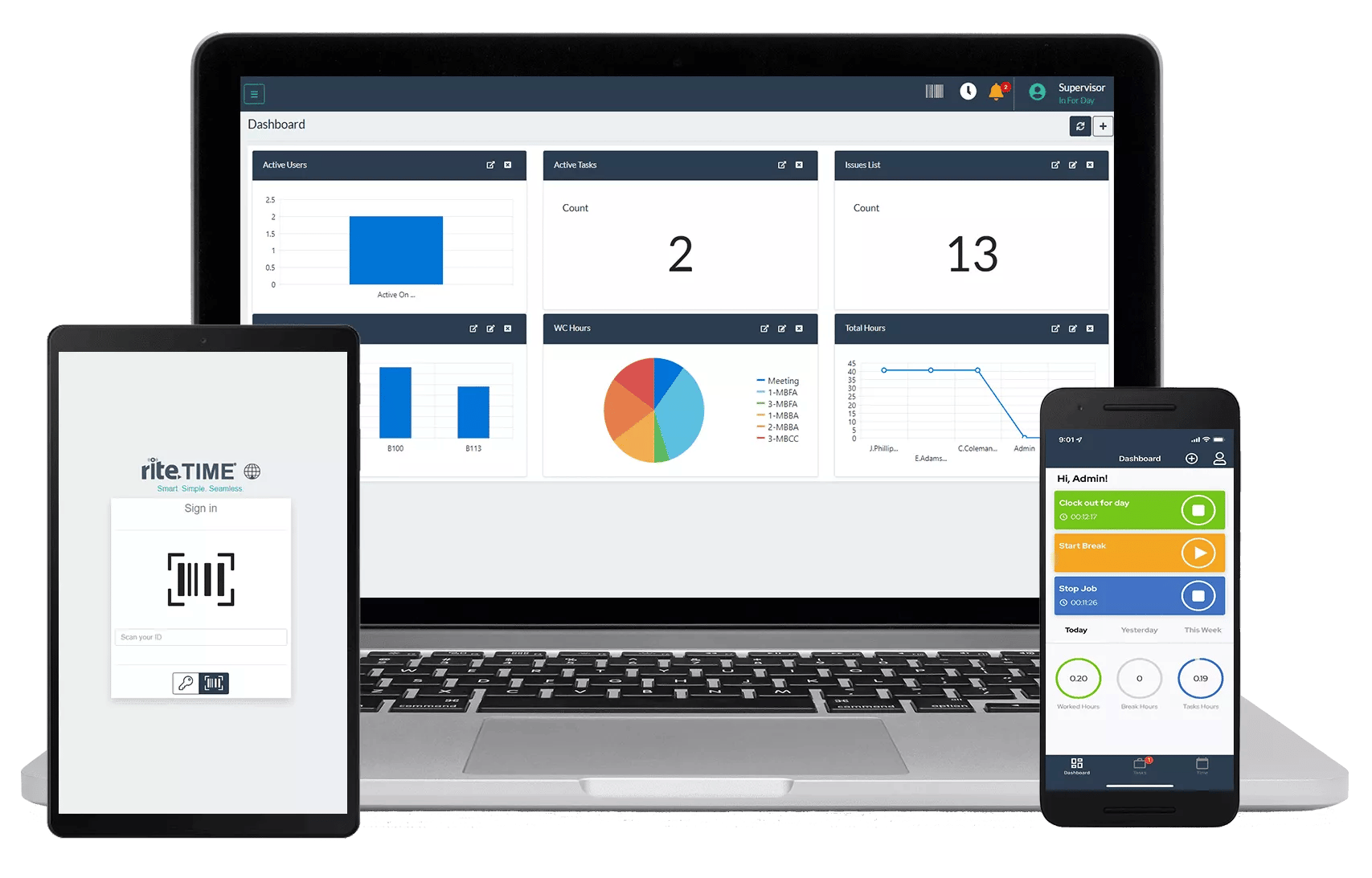

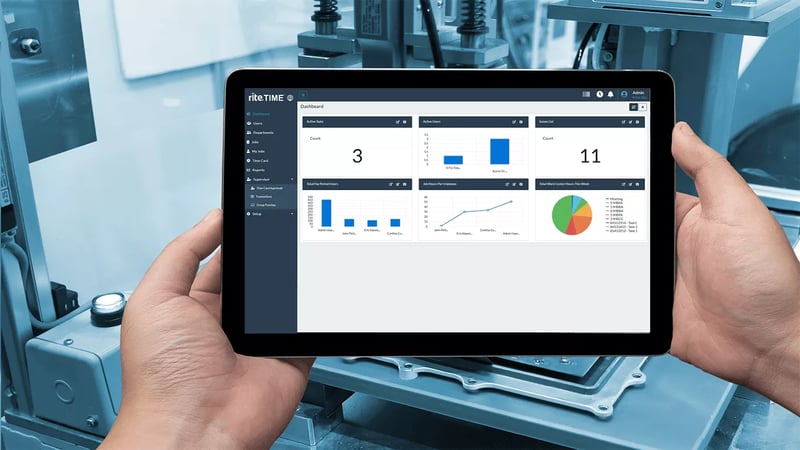

Get simple time tracking that matches the way shop floor operators and supervisors actually work.

Simple Screens

Simple screens to track direct and indirect time on Jobs and tasks by employee, department, work center, machine, and more.

Work Smarter

View job travelers, schematics, or instructions to help you work smarter. riteTIME provides visibility to how time is being used.

Instant Visibility

Get instant WIP visibility and monitor performance in real time to see where the issues are before they become big problems.